Page 55 - Zmist-n2-2015

P. 55

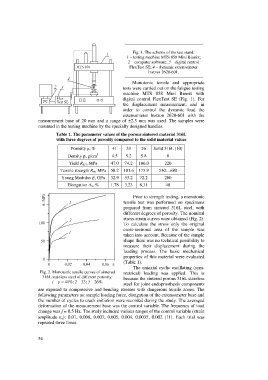

Fig. 1. The scheme of the test stand:

1 – testing machine MTS 858 Mini Bionix;

2 – computer software; 3 – digital control

FlexTest SE; 4 – dynamic extensometer

Instron 2620-601.

Monotonic tensile and appropriate

tests were carried out on the fatigue testing

machine MTS 858 Mini Bionix with

digital control FlexTest SE (Fig. 1). For

the displacement measurement, and in

order to control the dynamic load the

extensometer Instron 2620-601 with the

measurement base of 20 mm and a range of ±2.5 mm was used. The samples were

mounted in the testing machine by the specially designed handles.

Table 1. The parameter values of the porous sintered material 316L

with three degrees of porosity compared to the solid material values

Porosity p, % 41 33 26 Solid 316L [10]

3

Density r, g/cm 4.5 5.2 5.8 8

Yield R 0,2 , MPa 47.0 74.2 106.0 220

Tensile strength R m , MPa 58.2 101.6 175.9 530…680

Young Modulus E, GPa 32.9 53.2 72.2 200

Elongation A 5 , % 1.78 3.23 6.31 40

Prior to strength testing, a monotonic

tensile test was performed on specimens

prepared from sintered 316L steel, with

different degrees of porosity. The nominal

stress-strain curves were obtained (Fig. 2).

To calculate the stress only the original

cross-sectional area of the sample was

taken into account. Because of the sample

shape there was no technical possibility to

measure their displacement during the

loading process. The basic mechanical

properties of this material were evaluated

(Table 1).

The uniaxial cyclic oscillating (sym-

Fig. 2. Monotonic tensile curves of sintered metrical) loading was applied. This is

316L stainless steel of different porosity: because the sintered porous 316L stainless

1 – p = 41%; 2 – 33; 3 – 26%.

steel for joint endoprosthesis components

are exposed to compressive and bending stresses with dangerous tensile zones. The

following parameters as: sample loading force, elongation of the extensometer base and

the number of cycles to crack initiation were recorded during the study. The averaged

deformation of the measurement base was the control variable. The frequency of load

change was f = 0.5 Hz. The study included various ranges of the control variable (strain

amplitude e a): 0.01, 0.008, 0.007, 0.005, 0.004, 0.0035, 0.002 [11]. Each trial was

repeated three times.

54